The Future Direction for Tantalum Capacitors in the High-Tech Economy

05/05/2014 //

Solid tantalum capacitors are chosen for use in applications that require any combination of volumetric efficiency, long-term stability, high-temperature exposure, low noise generation and self-healing. Both manganese dioxide and conductive polymer-cathode type capacitors continue to evolve to deliver improvements such as lower equivalent series resistance (ESR), higher voltage handling capability, increased reliability and continual reductions in physical case size. This article examines the current state of the art for tantalum capacitor technology and its future direction that will enable the development of the electronic devices of the future that will continue to benefit and enhance our lives.

Tantalum Capacitors: Current Attributes and Applications

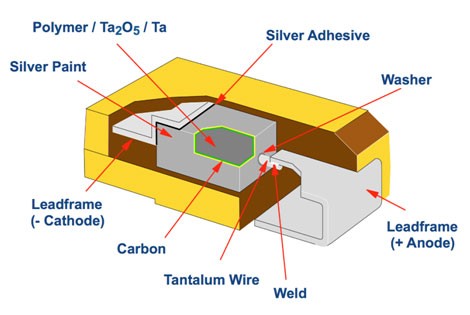

Solid tantalum capacitors are polarized electrolytic capacitors that are constructed with an anode of sintered pure tantalum metal powder, a dielectric layer of tantalum pentoxide (Ta2O5), and a cathode that can be manufactured from either manganese dioxide (MnO2) or an organic conductive polymer (e.g., PEDOT, polypyrrole or polyanaline- see Figure 1). The sintered anode has a high surface area which is the result of the extremely small particle size of the tantalum metal powder. The high surface area of the tantalum dielectric allows tantalum capacitors to offer high capacitance in a very small case size, which is ideal for the design engineer who needs capacitors to be volumetrically efficient, especially when designing printed circuit boards for today’s compact portable electronic devices.

Typical applications for tantalum capacitors include smoothing, filtering and decoupling in consumer and professional electronics. Tantalum capacitors offer high stability over a wide temperature range, as well as a self-healing capability which enhanced their reliability, making them ideal for use in automotive, military, aerospace and industrial electronics, as well as in high-end consumer products such as wireless handsets and tablet computers. These sectors currently are growing at healthy rates, typically 6%-11% for industrial, automotive and communications and as much as 20% for consumer multi-screen devices ensuring continued growth in demand for tantalum capacitors going forward.

Tantalum Capacitor Construction and Technology

Manganese Dioxide Tantalum Capacitors

Manganese Dioxide (MnO2) is the longest established cathode technology for solid tantalum capacitors. The cathode is formed by submerging a porous tantalum pellet covered with tantalum pentoxide into a solution that converts into MnO2. A tantalum wire embedded in the powder before sintering and subsequent formation of the dielectric provides electrical connection to the anode, and this in turn is welded to the anode terminal of the capacitor lead-frame. Graphite and silver contact layers are deposited on the cathode, which allow connection to the negative capacitor terminal. Figure 1 below shows a generic cross section of a moulded chip type surface mount tantalum capacitor.

Figure 1 - Cross-section of a Moulded Chip Surface Mount Tantalum Capacitor (Courtesy of KEMET Corporation)

This type of construction allows high volumetric efficiency because the tantalum particles allow the anode to have a large surface area. The ability to produce finer particle sizes allows manufacturers to produce tantalum capacitors with high capacitance-voltage per cubic centimetre of volume (CV/cc).

MnO2 cathode technology produces capacitors that have very low leakage current and high maximum temperature capability, reaching as high as 175°C or over 200°C (KEMET’S T500 series tantalum capacitor for example). In addition, the devices benefit from highly effective self-healing. Any defect causing increased current flow in localized areas results in heating that promotes conversion of MnO2 into manganese oxide (Mn2O3) which has lower conductivity and effectively heals the fault site and prevents further deterioration.

Strong demand continues for solid MnO2 tantalum capacitors for Commercial-Off-The-Shelf (COTS) applications, as well as automotive, industrial and other high-end applications that require long-term stability and high-temperature handling capability.

Tantalum Polymer Capacitors

An intense focus on energy efficiency in current system designs is driving demands for tantalum capacitors that offer lower Equivalent Series Resistance (ESR). ESR can best be described as the cumulative affect of various forms of resistance in the finished capacitor. Losses from resistance in a tantalum capacitor come from the various sub-components that make up the capacitor, most notably from the resistance of the material contacting the negative side of the tantalum dielectric. Low-ESR MnO2 capacitors are evolving to address these demands. However, the relatively high resistivity of MnO2 represents a barrier to further significant reduction of ESR in tantalum capacitors.

However, tantalum polymer capacitors overcome this limitation by replacing the conventional MnO2 cathode with an organic conductive polymer. This class of conductive polymer capacitor has significantly lower ESR when compared to that of an MnO2 type tantalum capacitor.

Tantalum polymer capacitors are successful in cost-sensitive non-consumer applications, and also are becoming increasingly competitive in lower-end product designs. In particular, the growth in markets for small consumer devices that leverage system-on-chip integration to provide high compute power is driving demand for the high-performance/price ratio offered by tantalum polymer capacitors compared to alternative dielectrics.

The further development of tantalum polymer capacitors is continuing, and is focused on the continual reduction of ESR, increasing maximum voltage capability, and achieving smaller and thinner package sizes. With continued improvement, tantalum polymer capacitors are becoming increasingly attractive in end-market circuit applications that demand high-reliability performance.

Tantalum Capacitors: Technology Roadmap

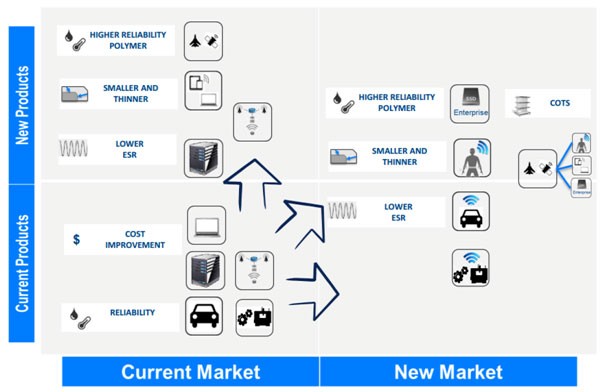

The following Figure (Figure 2 below) illustrates current tantalum capacitor products for current markets, and new product developments in tantalum capacitors for new markets.

Current Products for Current Markets

Both manganese dioxide and conductive polymer type tantalum capacitors are currently employed in a myriad of standard, professional and mission critical circuit applications worldwide to provide smoothing, filtering and decoupling. These circuits can be found in computers, wireless handsets, automotive safety solutions, smartphones, test and measurement equipment, oil and gas systems, medical implants and defense electronics. Additionally, tantalum capacitor manufacturers continue to reduce production costs by exercising greater control over their supply chains.

New Products for New Markets

Moving into 2014, tantalum manufacturers are continuing to set the pace with innovations like automotive-grade polymer capacitors, polymer capacitors in hermetically sealed packages, high voltage polymer capacitors, more polymers available with rated temperatures up to 125°C, and ultra-low-ESR polymer capacitors in extremely thin (1.0mm) and small packages. Additionally there will be added cost savings in production by controlling the powder development stage to packaging of a completed capacitor, we will see other innovations, new product families, and family-extensions over the next calendar year to service emerging markets such as wearable electronics, thinner tablets and handsets, advanced medical devices; updated automotive electronic systems; next generation oil and gas pumping and logging systems and advanced aircraft and spacecraft.

Figure 2. Tantalum Capacitors: Current Products for Current Markets and New Products for New Markets.

Summary and Conclusions

In this MarketEYE instalment it has been established that solid tantalum capacitors are chosen in applications that require any combination of volumetric efficiency, long-term stability, high-temperature exposure, low noise generation and self-healing capabilities. This includes smoothing, filtering and decoupling applications in computers, wireless handsets, automotive safety solutions, smartphones, test and measurement equipment, oil and gas systems, medical implants and defense electronics. New tantalum capacitors with enhanced capabilities, such as lower ESR, lower profiles, higher temperature handling capabilities and advanced packaging will be enabling technology for emerging markets in wearable electronics; as well as for the extension and growth of a variety of new end products currently being designed in computers, communications, automotive, medical, defense and aerospace platforms for future deployment worldwide.

Dennis M. Zogbi

Dennis M. Zogbi is the author of more than 260 market research reports on the worldwide electronic components industry. Specializing in capacitors, resistors, inductors and circuit protection component markets, technologies and opportunities; electronic materials including tantalum, ceramics, aluminum, plastics; palladium, ruthenium, nickel, copper, barium, titanium, activated carbon, and conductive polymers. Zogbi produces off-the-shelf market research reports through his wholly owned company, Paumanok Publications, Inc, as well as single client consulting, on-site presentations, due diligence for mergers and acquisitions, and he is the majority owner of Passive Component Industry Magazine LLC.