Amphenol

Connector Assembly

Connector Assembly

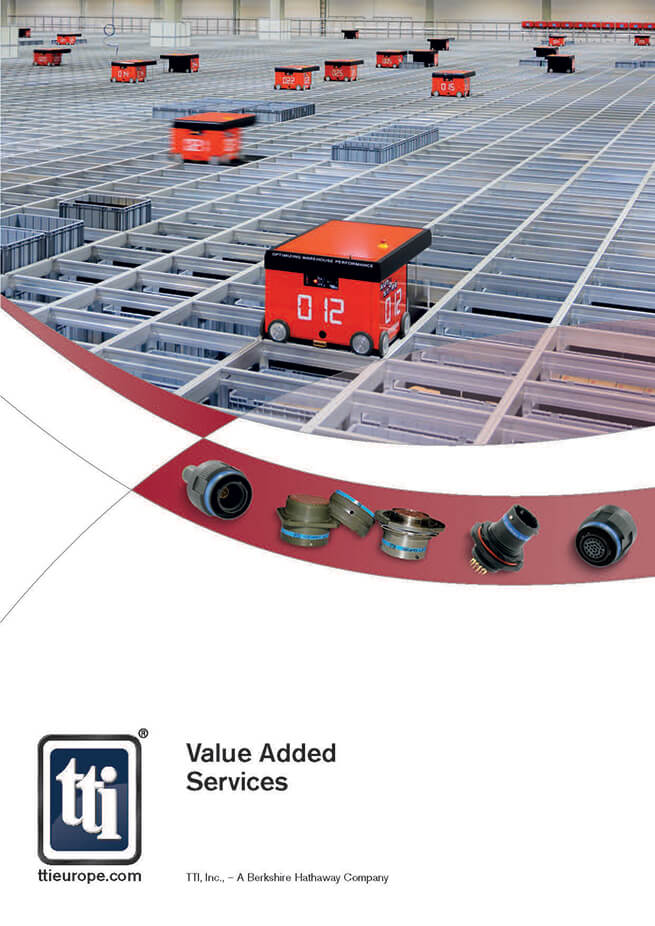

Here at TTI Europe, we specialize in distributing connectors and interconnect solutions from top suppliers recognized around the world. We carry stock of ready-made connector components and we also have the ability to custom-create the connector to fit your unique application.

Our state-of-the-art connector assembly line is QPL approved, and all of our lines are officially authorised by our suppliers including Amphenol, ITT Canon/ VEAM, Souriau, and TE Deutsch. With the capacity of building more than one million different variants of connectors and an outstanding stock level of components, we can ensure short lead times, a minimum of 48-hour turnaround upon request, without any MOQ, ship to your forecast requirements or simply hold buffer/safety stock to meet your procurement needs.

With the integration of COSY Connector Systems, we now also specialize in the assembly of circular connectors from the world-recognized manufacturer ITT Cannon/ VEAM. With the COSY portfolio (Cannon: VG95234, CA-B, CA, VG95328, KPSE, KPT, KPTC, CGL / VEAM: FRCIR, CIR) now part of TTI, we offer industry leading capabilities to customize and create the right interconnect solution for all your production or project requirements.

Custom-fit circular connectors are built on-demand at TTI, from the largest European inventory of individual components (insert, barrel, backshell, o-ring, contacts, etc.), and our team focuses on the latest technology with an intensely sophisticated workflow, allowing quick turnaround time.

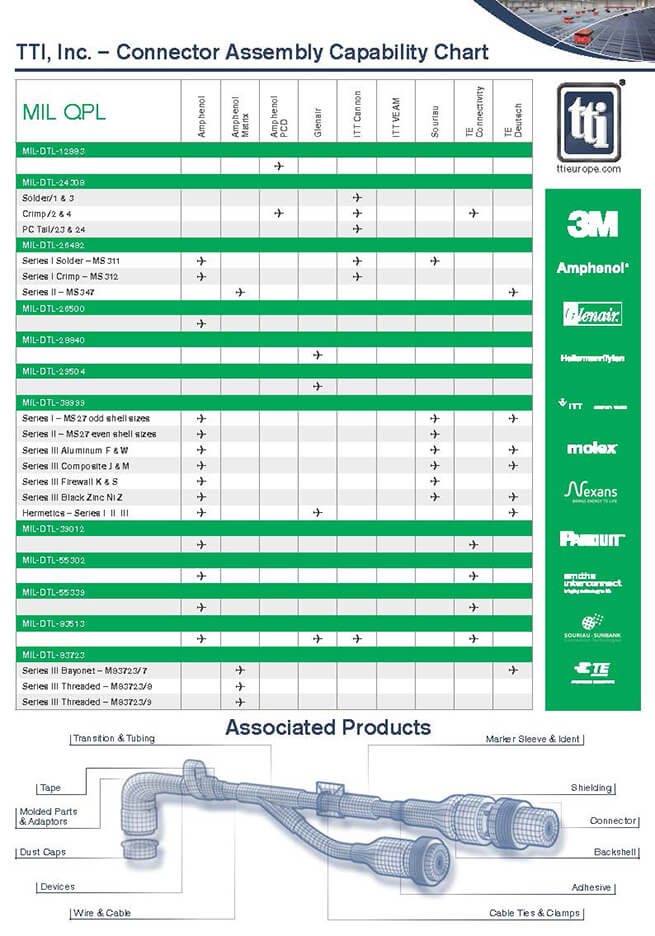

A large part of our assembly focus is on the MIL-DTL-38999 Series I & III, HE308, VG96912, VG95234 and SJT Circular Connectors. In addition, we also assemble the MIL-DTL-26482, VG95328, 97, PT, 851 and VGE1 Series for industrial and harsh environments. We are ISO 9001:2015, as well as EN9100:2018 and EN9120:2018 certified to ensure the highest level of quality and service.

We are ISO 9001:2015, as well as EN9100:2018 and EN9120:2018 certified to ensure the highest level of quality and service.

Our Offerings

Plating

- Olive drab cadmium

- Electroless nickel

- Zinc cobalt black

- Zinc nickel blue

- Black zinc nickel plating

- Stainless steel

- Marine bronze

- Epoxyurethanic varnish black

J-Plating

- Ultra-harsh environment formulation

- Meets or exceeds the VG (German Military) performance requirements of cadmium

- Highly conductive (< 5m ohm)

- Corrosion-resistant

Contacts

- Signal (solder & crimp)

- Power

- Coaxial and PCB (including stand-off) contacts

Accessories

- Backshells

- Cable Glands

- Boots

- Adapters (ME-, PG-, Angle- & Bandlock-Adapter)

Cable Management

- Transition & Tubing

- Tape

- Molded Parts & Adaptors

- Dust Caps

- Devices

- Marker Sleeve & Ident

- Shielding

- Connector

- Backshell

- Adhesive

- Cable Ties & Clamps

Benefits as a developer:

Reliable technical advice and customer-specific solutions

Custom-fit solutions, specific combinations: custom made circular connectors

Take advantage of our consistently customer-oriented service, from the individual technical support for developers all the way to technical application consulting through sales.

- Technical support

- Customer specific solutions

- Customer-oriented stocking

Benefits as a purchaser:

Customer-oriented stocking and professional contact people

Wide portfolio, prestigious brands, many years of experience as distributor

Profit from our consistently customer-oriented service, the individual technical support and customer oriented stocking.

- Huge inventory

- Customized labelling

- Packaging according to customer requirements

Applications

Defense, Aerospace & Space

- D38999 / MIL-DTL-38999-Serie-I

- D38999 / MIL-DTL-38999-Serie-III

- CA / MIL-DTL-5015

- VG95234/ CA-Bayonet

- VG95328 / KPT / KPSE / KPTC

- VG96912 / CGK

Transportation

- FRCIR / CIR

- CA-Bayonet

- GCB-B

- KPT / KPSE / KPTC

- PT

- CA-COM

- Series 851

- VGE1

Industrial

- CA-COM / CA-COM Bayonet

- CGL / CGL-B

- VG95234 / CA-Bayonet

- VG95328 / KPT / KPSE / KPTC

- CA / MIL-DTL-5015

- VG95328 / KPT / KPSE / KPTC

- PT

- GCB-B

- Series 851

Featured Products

Additional Information

Certificates

- TTI ITT Cannon Certificates (PDF)

- TTI ITT VEAM Certificate (PDF)

- TTI Eaton Certificates (PDF)

- TTI Amphenol Socapex Certificates (PDF)

- TTI ITT Cannon Certificates (PDF)

- TTI ITT VEAM Certificate (PDF)

- TTI EATON Certificate (PDF)

- TTI Amphenol-Air LB Certificate (PDF)

- TTI Defense Logistics Agency Certificate (PDF)